Technologies

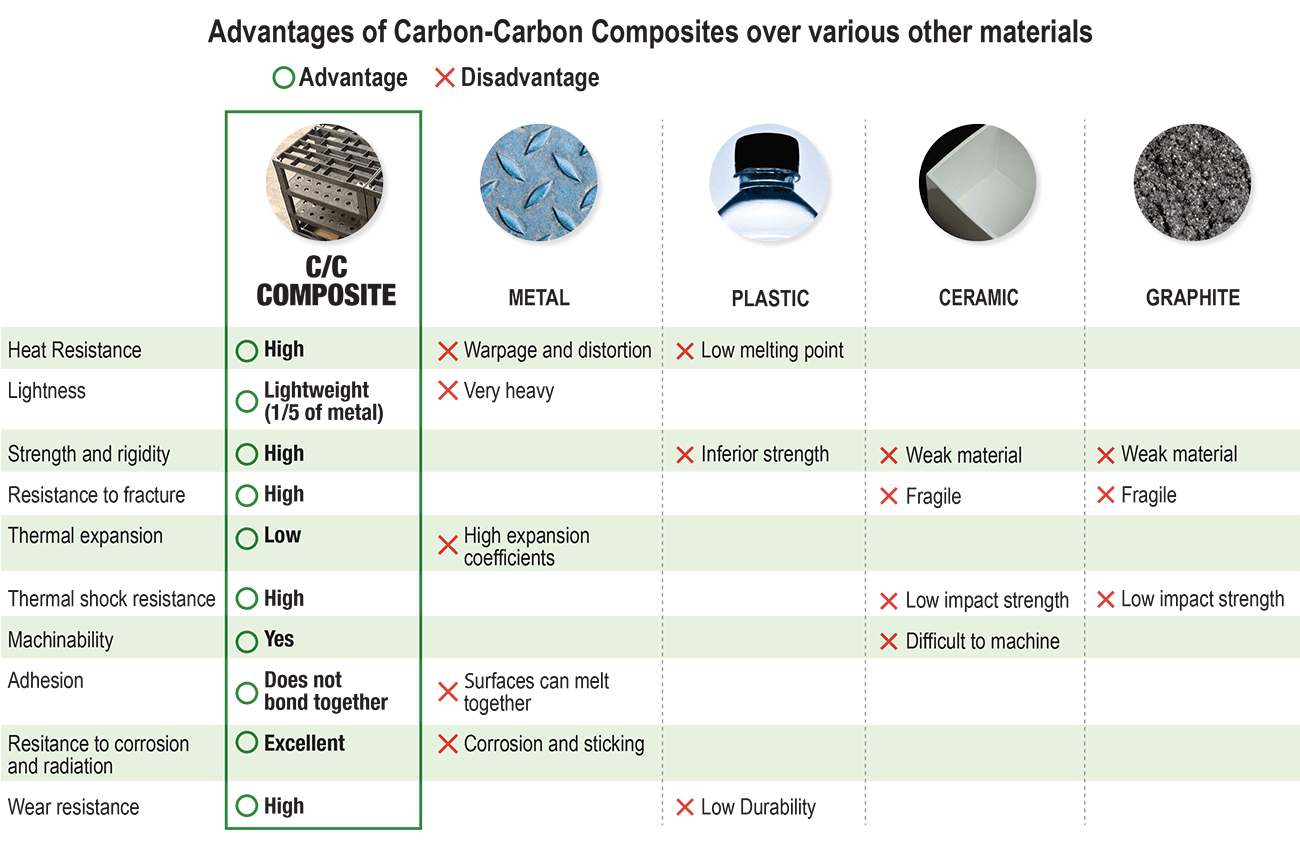

Carbon-Carbon, C/C Composite / Material Comparison

CFC Design Technologies

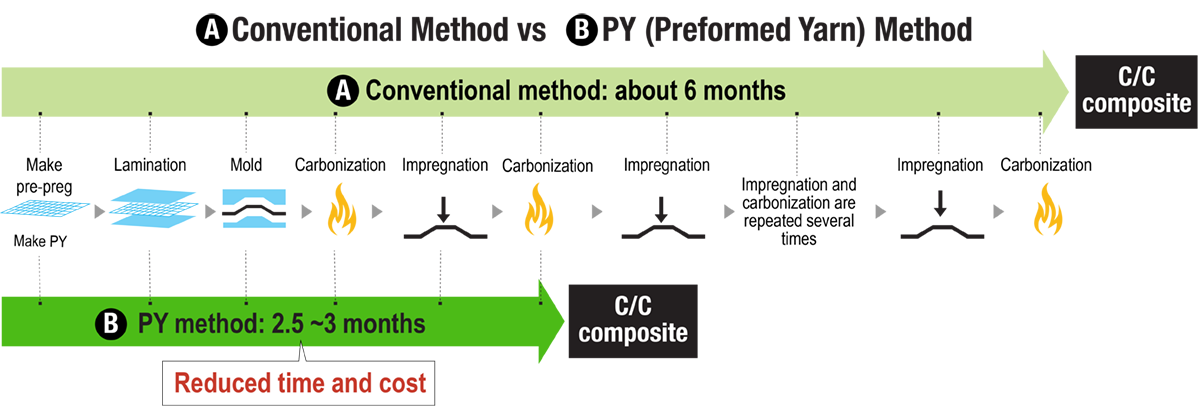

Preformed Yarn Method

Although the Carbon-Carbon, C/C Composite has excellent performance, the conventional manufacturing method (impregnation method and CVD method) requires complicated steps and requires very long time to manufacture. And as a result it was extremely expensive. CFC Design have succeeded in a process simplification, shortening delivery time and reducing costs by developing innovative new manufacturing method called preformed yarn method (PY method).

Fiber Orientation

By controlling the directional arrangement and the length of carbon fiber reinforcement that supports the carbon matrix, we are able to change the characteristics of the Carbon-Carbon, C/C Composite so that it can be used for different kinds of application.

Fiber orientation

Fiber length

Features

Application

- Bolts

- Nuts

- Precision jigs

- Trays

- Plates

- Large-size components

Long fiber

- High-strength rods

- Springs

- Pins

CFC Design Capabilities and Solutions

Materials Design

CFC Design's manufacturing technology has designed and created a variety of Carbon-Carbon, C/C Composite manufacturing techniques over the years with precision and accuracy. Custom Carbon-Carbon, C/C Composite material grades can be tailor-made to help with specific engineering challenges and help the customers reach their goals.

We employ various types of manufacturing techniques and special services which have been accumulated over many years.

Engineering Design

CFC Design's engineering design team works closely with every customer to develop a suitable Carbon/Carbon, C/C Composite design solution for their specific product. The engineering team can perform a structural stress analysis to ensure your product will perform as intended in a defined load environment.

With prompt product planning, production, assembly, testing, and evaluations, our support team will work with each customer to exceed performance requirements and to provide outstanding Carbon-Carbon, C/C Composite design products.

Other Services and Solutions

When we hear the word “carbon”, much of what we hear is about carbon emissions into the atmosphere, and the negative impact on global warming through the greenhouse-gas effect. Although this is important, it is a result of carbon in the atmosphere in the form of carbon-dioxide gas. But carbon also takes on other solid forms, such as Carbon-Carbon, C/C Composite which is quietly gaining acceptance as an advanced carbon material that is able to significantly reduce energy consumption in today’s manufacturing world.

At CFC Design, we are continuously connecting materials, processes, systems and design to serve as the trusted advisor guiding manufacturers toward a smarter manufacturing future to support our global economy and enhance sustainable development.

Sustainability at CFC Design

Providing Material Design Innovations by Advanced Carbon Technologies to Help Address Global Issues

When we hear the word “carbon”, much of what we hear is about carbon emissions into the atmosphere, and the negative impact on global warming through the greenhouse-gas effect. Although this is important, it is a result of carbon in the atmosphere in the form of carbon-dioxide gas. But carbon also takes on other solid forms, such as carbon-fiber reinforced carbon composite which is quietly gaining acceptance as an advance carbon material that is able to significantly reduce energy consumption in today’s manufacturing world.

At CFC Design, we are continuously connecting materials, processes, systems and design to serve as the trusted advisor guiding manufacturers toward a smarter manufacturing future to support our global economy and enhance sustainable development.

Lightweight Innovations and Design

Parts made from Carbon-Carbon, C/C Composite material are thinner and lighter than those made from conventional material.

Increased Productivity and Energy Savings

Due to the compactness of Carbon-Carbon, C/C Composite design fixtures, more material can be loaded into the process resulting in increased productivity.